Product Service

Contact Us

+886 07-7882366

Services

Business items

- Precision Parts Manufacture

- Vacuum Chamber Manufacture

- Vacuum Parts Manufacture

- Modular Assembly

- Embedded small high pressure pump

Our main business is the manufacturing of precision equipment parts, vacuum chambers, fixtures, and assembly of equipment modular, etc.

The industry covers the manufacturing and processing of traditional industries, optoelectronic industries, semiconductor industries, passive component industries, energy industries, automobile and motorcycle industries, and mold industries.

CHING CHEE takes service, innovation, speedy, and integrity as its quality policies, and uses innovative management methods and technological integration capabilities for excellence to continuously achieve the product quality required by customers, and continue to grow towards the goal of sustainable development of the company.

At present, we are actively cooperating with international optoelectronic equipment manufacturers (ULVAC and MIC) and various international as well asJapanese suppliers to carry out a strategic partnership so as to provide optoelectronic equipment mechanical parts.

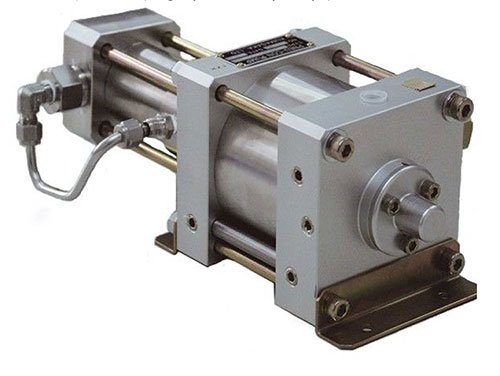

Embedded small high pressure pump

We are the agent for Technomate Co., Ltd., Japanese original manufacturer of high-pressure pump, medical machinery, semiconductor, automated production machinery, crystal, and chip cleaning machine. The liquid sprayed during the polishing of computer screens and mobile screens can be installed and used.

Applicable industries: semiconductor wet process, medical equipment, automation industry, panel industry.

Manufacture of precision equipment components

Component material requirements:

Common materials for the vacuum chamber and vacuum parts are stainless steel (SUS304 / SUS316), aluminum alloy (A5052 / A5083), steel and other metals, and various types of socket weld flange KF fitting pipe and customized water channel elbow (stainless steel sus and copper) production.

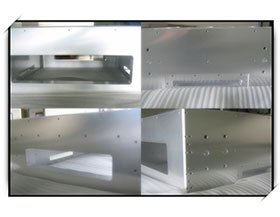

Aluminum chamber processing

Customized aluminum chamber processing

Vacuum Parts Manufacture

Customized aluminum cavity processi:

Vacuum Parts Manufacture- stainless steel

Vacuum Parts Manufacture- Pipe

Vacuum Parts Manufacture- titanium alloy

Vacuum Parts Manufacture -copper

Vacuum Parts Manufacture aluminum alloy

CNC Manufacture

Mold parts processing and Manufacture, aluminum alloy processing and Manufacture, metal and non-ferrous metal processing and Manufacture, electronic components processing and Manufacture, medical components processing and Manufacture, mechanical components processing and Manufacture, other special parts Manufacture, and various mechanical customized processing and Manufacture.

Welding Manufacture

Vacuum cavity welding processing and Manufacture, iron welding processing and Manufacture, stainless steel welding processing and Manufacture, vacuum pipe welding processing and Manufacture, component related welding processing and Manufacture, aluminum alloy welding processing and Manufacture

Record the necessary welding parameter conditions for each welding method according to WPS/PQR, confirm the parameters according to PQR, and welding audit by professional AWS inspectors, and perform the qualification examination of each welder’s technician, and implement the WPS system of the whole factory

Production line processes

- Customer Orders→Production

anagement→processing - (Outsource processing、in-plant

rocessing)→Finishing treatment→Quality control hecks→Wash→Packaging and Shipment‧

On September,2011 has completed ISO9001:2008 Quality management system certification‧